SFI Manufacturing as a birthplace for new projects

SFI Manufacturing has an important role as an incubator for spin-off projects, such as user driven innovation projects (supported by the Research Council of Norway) and collaborative projects (supported by the European Commission). As mentioned earlier, the centre’s ambition is to generate a total portfolio of spin-off projects, with a total budget of 800 million NOK, over the 8-year centre period.

In the past few years, we have developed a process model for the development and implementation of new project ideas, to ensure the complementarity and relevance of the research throughout the centre’s period. Already after 3,5 years of operation, we have succeeded to establish a total activity exceeding 80% of the ambition of the 8-year period. All partners of SFI Manufacturing are also partners in one or more spin-off projects.

In addition to this, SFI Manufacturing has been the birthplace for 1) the Norwegian Manufacturing Research Laboratory MANULAB, 2) Manufacturing Technology Norwegian Catapult at Raufoss, a centre where industrial companies have the possibility to test new technologies and solutions, and 3) “Omstillingsmotoren”, a national and open arena for learning and innovation across different industries in Norway, and in particular SME's, with a focus on Lean through the project “Produktivitetsspranget”. The last two initiatives are important dissemination arenas for SFI Manufacturing, and will have an important role to stimulate commercialisation outside the SFI Manufacturing consortium.

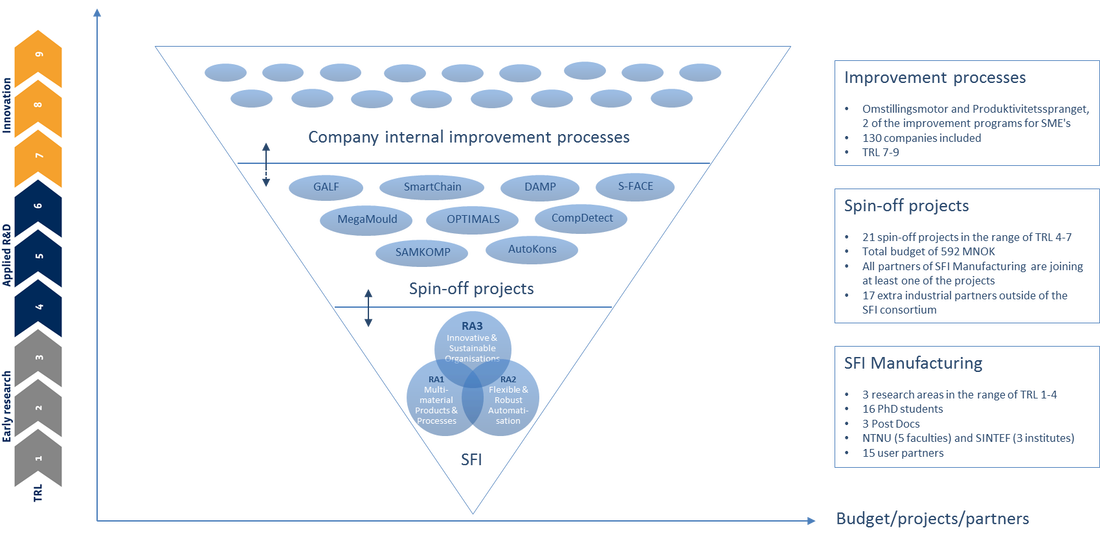

The value chain from SFI Manufacturing research, through the spin-off projects and activities, is the model for innovation associated with our SFI. This can be illustrated by the following figure:

In the past few years, we have developed a process model for the development and implementation of new project ideas, to ensure the complementarity and relevance of the research throughout the centre’s period. Already after 3,5 years of operation, we have succeeded to establish a total activity exceeding 80% of the ambition of the 8-year period. All partners of SFI Manufacturing are also partners in one or more spin-off projects.

In addition to this, SFI Manufacturing has been the birthplace for 1) the Norwegian Manufacturing Research Laboratory MANULAB, 2) Manufacturing Technology Norwegian Catapult at Raufoss, a centre where industrial companies have the possibility to test new technologies and solutions, and 3) “Omstillingsmotoren”, a national and open arena for learning and innovation across different industries in Norway, and in particular SME's, with a focus on Lean through the project “Produktivitetsspranget”. The last two initiatives are important dissemination arenas for SFI Manufacturing, and will have an important role to stimulate commercialisation outside the SFI Manufacturing consortium.

The value chain from SFI Manufacturing research, through the spin-off projects and activities, is the model for innovation associated with our SFI. This can be illustrated by the following figure:

The spin-off projects are also an important arena for transfer of competence and results from the centre to the partners, and feedback from the industry partners regarding potential revised research issues. This is achieved through direct links between centre activities and the spin-off projects, for example via researcher and PhD students. The centre also provides updated state-of-the-art reports/presentations on several different research topics within the scope of SFI Manufacturing. These SOTAs are intended to be useful both directly for the user partners and as a basis for spin-off projects.