I started my PhD with experimental studies of the elasto-visco-plastic response of a novel but commercialised thermoplastic elastomer prepared by vulcanization (TPV). One significant aspect is sample preparation and geometry (figure 1), and another is handling and treating the experimental data (strain) output. As the experimental methodology in itself is a target for the PhD, a selected few more materials will be studied subsequently.

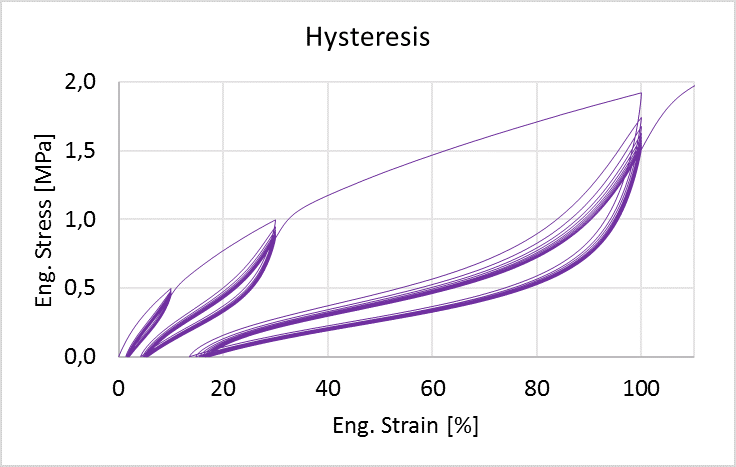

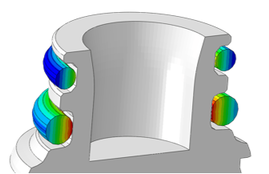

In parallel, materials models are intended calibrated and verified, primarily for a selection of published material models, including behavioural features of non-linear nature and time-temperature dependency. I am currently immerged in 10-15 years of publications of rubber and elastomer material models. One major challenge is to adequately describe the complex mechanical response with a model also suitable for industrial use. Figure 2 is an example of one characteristic of elastomer mechanical response.

RSS Feed

RSS Feed