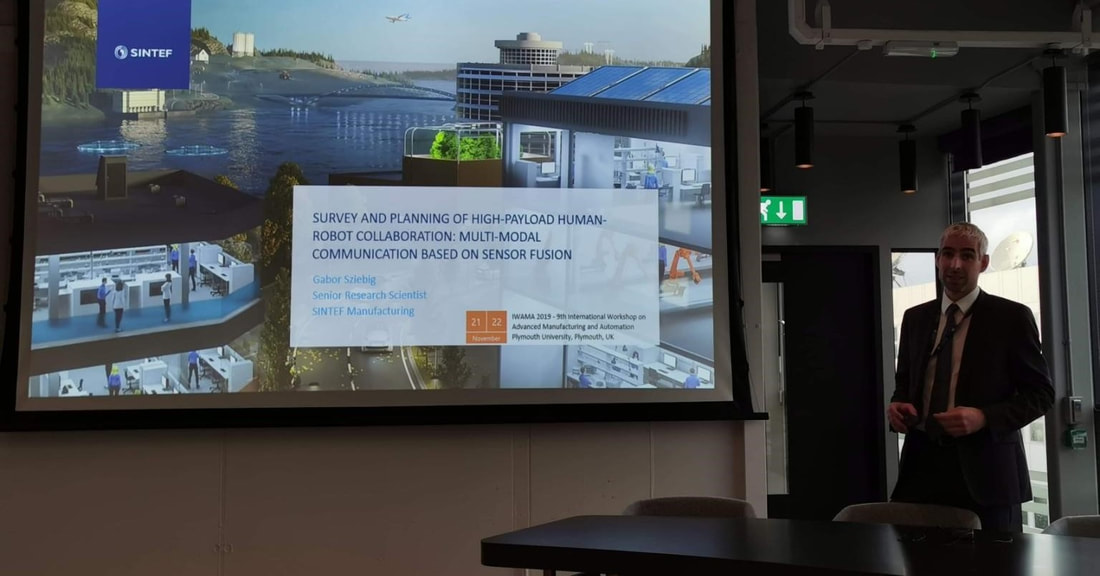

On the 21st and 22nd of November, the 9th edition of IWAMA took place in the United Kingdom, at the Plymouth University. Researchers of SFI Manufacturing travelled to Plymouth to join the conference.

IWAMA – International Workshop of Advanced Manufacturing and Automation – is an important international conference on advanced manufacturing and automation, and takes place in China or the United Kingdom every year.

Manufacturing and automation has assumed paramount importance and are vital factors for the maintenance and improvement of the economy of a nation and the quality of life. The field of manufacturing and automation is advancing at a rapid pace and new technologies are also emerging in the field. The challenges faced by today’s engineers are forcing them to keep on top of the emerging trends through continuous research and development.

IWAMA aims at providing a common platform for academics, researchers, practicing professionals and experts from industries to interact and discuss trends and advances in some areas of manufacturing and automation, while sharing ideas and perspectives.

Tone Gjerstad and Gabor Sziebig joined as researchers from SFI Manufacturing – Research Area 2. Many other colleagues from SINTEF joined as well, such as Eirin Lodgaard, Ragnhild Eleftheriadis, Davar Hemyari and Even Wilberg Hovig, who contributed with presentations on the latest proceedings in the scientific field of advanced manufacturing and automation.

RSS Feed

RSS Feed