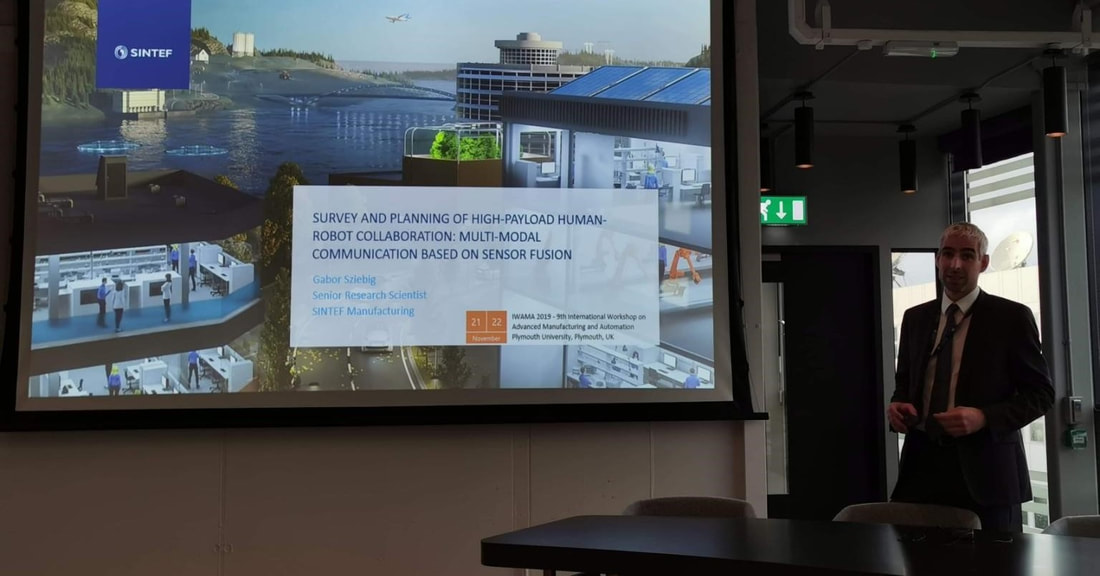

– My thesis has two main topics: An idealized automatic assembly system, capable of generating and executing robot programs based on CAD models, and closed-loop inverse kinematics systems for on-line control of an industrial manipulator, explains Mathias.

The thesis is a collection of papers related to these topics written during Mathias’ work at SFI Manufacturing. The accompanying text in the thesis gives a brief introduction to the history of robotics, as well as an overview of some of the robotics literature.

Mathias started his SFI Manufacturing Postdoc Spring 2019. During his Postdoc he will be working on high-level planning and control of articulated robots for assembly, exploiting expert knowledge and CAD information.

Read Mathias his thesis here

Find the presentation of the defendence (and video) here

RSS Feed

RSS Feed