SFI Manufacturing is a cross-disciplinary centre for research-based innovation for competitive high value manufacturing in Norway. The centre is hosted by SINTEF Manufacturing AS, it has 14 industry partners, and SINTEF and NTNU as research partner. An analysis of the independent advisory firm Impello Management AS shows that the centre potentially can have an economic impact of >3 billion NOK per year in the Norwegian manufacturing industry.

SFI Manufacturing has been awarded 30 IPN projects in the period of 2016-2019. The analysis of Impello Management AS is based on 15 of these projects started in 2018, and statements of the industry partners in relation to these projects. To realize the potential economic impact, significant investments from the industry will be required.

More potential impact

The analysis shows more potential economic impacts in addition to the 3 billion NOK as well: Reduced operating costs, increased profits and reduced investments. These impacts are based on 8 use cases linked to the 15 IPN projects. The use cases are subsequently linked to one or more of the centre's research areas: Multi-material products and processes, Flexible and robust automation, and Sustainable and innovative organizations.

Specifically, the 8 use cases are covering the fields of:

- New joining methods for high-performance aluminum-steel products

- Additive manufacturing of elastomer products

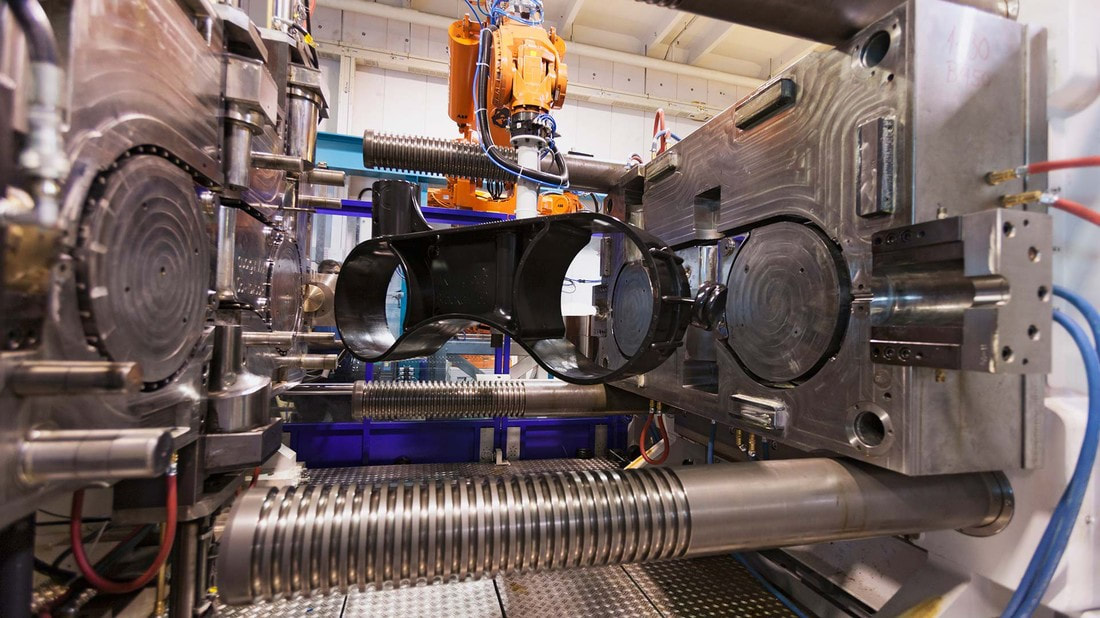

- Robust robotic motion planning for manufacturing

- Software architecture and tools for «batch size one» robotic assembly

- 3D vision: Deep learning for robotic grasping

- Benchmarking enterprise development maturity

- Modernization of vocational education and training

- Alignment of management tools

It is in these fields where the potential economic impact of SFI Manufacturing lies.

Key facts about SFI Manufacturing

- Centre for research-based innovation (2015-2022) hosted by SINTEF Manufacturing AS, which has its main basis at Raufoss Industry Park, Oppland.

- Industry partners: Benteler Automotive, Brødrene Aa, Ekornes, GKN Aerospace Norway, Hexagon Raufoss, HyBond, Hydro, Kongsberg Automotive, Mjøs Metallvarefabrikk, Nammo, Neuman Aluminium, Plasto, Rolls-Royce, Sandvik Teeness.

- Research partners: SINTEF, NTNU.

- Research areas: Multi-material products and processes, Flexible and robust automation, Sustainable and innovative organizations.

- Turnover: The budget for 2015-2022 is 202 MNOK. In addition, the centre has been awarded 30 IPN projects in the period of 2016-2019, with a total value of 850 MNOK.

- PhD, Postdoc and Masters (31.10.2019): PhD: 1 finished + 12 ongoing + 3 planned, Postdoc: 2 ongoing + 2 planned, Masters: 25 completed + 75 planned.

- Scientific publications (09.12.2019): >85

Contact person

- Sverre Gulbrandsen-Dahl, Centre Manager of SFI Manufacturing. Email: [email protected], phone number: +47 916 01 205.

RSS Feed

RSS Feed