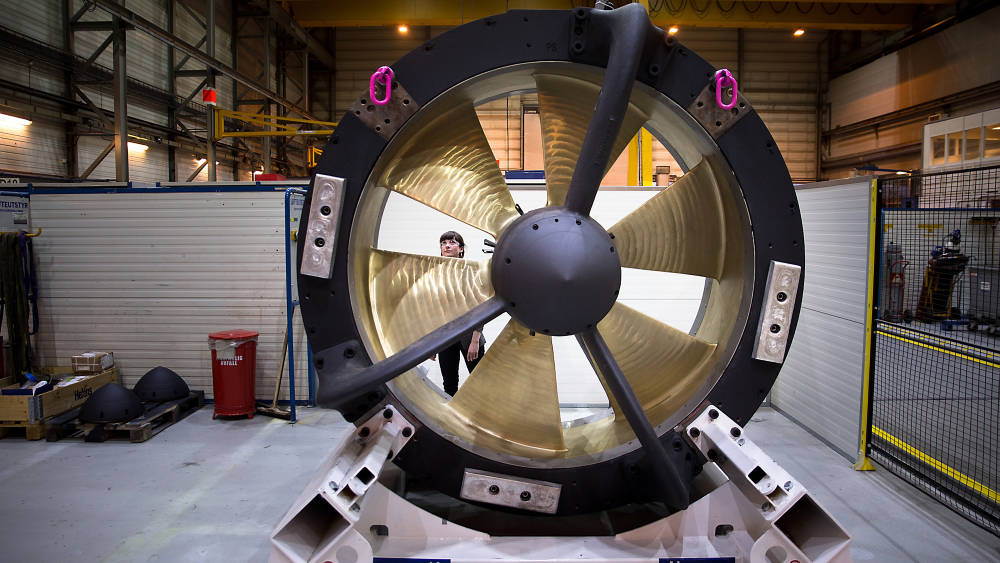

The industrial cluster NCE Raufoss is a national competence centre for light weight materials and automated production in Norway. Nammo, Benteler, Kongsberg Automotive, Hexagon Ragasco, Raufoss Technology, Plastal, NTNU and SINTEF Raufoss Manufacturing are members of NCE Raufoss, as well as partners of SFI Manufacturing.

The project period of ten years ends this summer and the statistics show a very good productivity development. When you're based in a high cost country like Norway, productivit is a key factor in order to compete internationally. On Febryary 3rd, NCE Raufoss published a chronicle in Oppland Arbeiderblad about its achievements so far.

Read the chronicle in Oppland Arbeiderblad here (pdf).

RSS Feed

RSS Feed